Power up your workflow with SigmaNEST Copilot & the Connect Portal

Learn how the power duo of Copilot AI and the Connect Portal can upskill your nesting and improve your fabrication output.

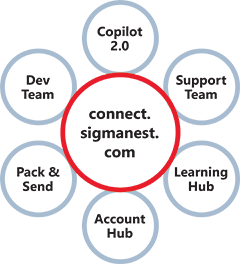

The SigmaNEST Connect Portal is the epicenter for engaging with your software and getting tangible improvements that matter in your shop.

1. Tour the portal at Connect.SigmaNEST.com

- SigmaNEST Copilot 2.0 software guide

- Info hub for IT, engineering & managers

- Online Pack & Send for support

- Rally our development team on future features

- Manage cases, users, account status, updates, downloads, usage & more

2. Explore Copilot 2.0!

The new version of SigmaNEST Copilot is even smarter, with instant answers (and reference links!) on all things SigmaNEST, any time, in 19 different languages.

Be your own best advocate for uptime productivity and business competitiveness with the Copilot AI and Connect Portal power duo!